The new Digitale S-Bahn Hamburg 2.0 system will be tested until the UITP World Congress in June 2025. The project, costing €35m, is jointly funded by DB, the city of Hamburg, and Siemens Mobility.

The intelligent operations system of the Digitale S-Bahn Hamburg 2.0 saves energy through two approaches. With the technology knowing the exact positions of all trains in the network, rolling phases can be better utilized, and stops on the track can be avoided.

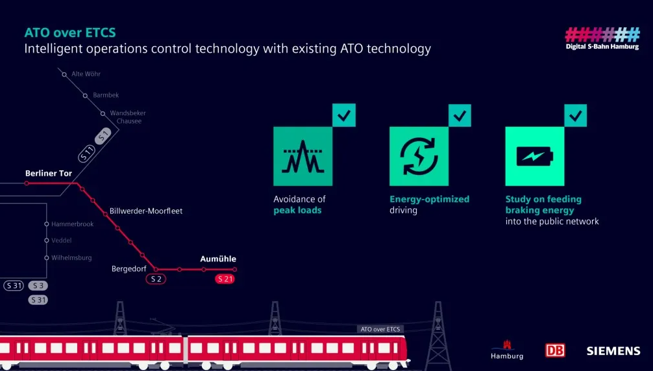

Furthermore, the system reduces peak loads in power consumption by preventing multiple trains from starting simultaneously on the track. The project will also include a study to investigate the potential of energy recuperation through inverters into the public power grid.

The technology of the Digitale S-Bahn Hamburg is already in daily use for passengers. Four digitally controlled trains are currently operating on the Hamburg route between Berliner Tor and Bergedorf. Meanwhile, 64 new S-Bahn trains equipped with digital technology have already been ordered.

By the end of the decade, the city area of the S-Bahn Hamburg is planned to be equipped with the digital system. In 2021, the partners of the Digitale S-Bahn Hamburg jointly introduced the world’s first highly automated train in an open railway system.

Dr Kristian Weiland, DB head of development, Digitale Schiene Deutschland, said, “With the Digital Rail program, we will operate trains even more energy-efficiently in the future. In addition to providing additional capacity and higher reliability, the technology has the potential to reduce energy consumption by up to 30%, according to initial estimates. Considering the current energy demand of the S-Bahn Hamburg, we would save the energy consumption of 10,000 households per year in the Hanseatic city alone. Here at the S-Bahn Hamburg, we are developing the technology that will later be used nationwide.”

Michael Peter, CEO of Siemens Mobility, added, “Together with our partners, we have shown that, within a short period, automated rail transport is possible in an open railway system for the first time. With Digitale S-Bahn Hamburg 2.0, we are now taking the next step, developing, and testing globally innovative functions for the highest energy efficiency. This is an important step towards reducing CO2 and operating costs, and it is part of the most significant technological change on the railway, which we are driving forward together here in Hamburg.”

Kay Arnecke, managing director S-Bahn Hamburg, concluded, “The new project is another step towards the digitization of the S-Bahn Hamburg. We have been very successful with the pilot route of the Digitale S-Bahn in passenger service since last September. Now we can create further prerequisites for an efficient and energy-saving digital S-Bahn operation of the future.”