To find out more information about the online conference, which is being held on March 17 2022, 9am-5pm GMT, and to register for your free pass, click here. The event will bring together leading rail experts to discuss everything from batteries, charging solutions, hydrogen, fuel cells and electric motors to power electronics, real-world case studies and future concepts, plus much more.

What will you be discussing during the Electric & Hybrid Rail Technology Online Conference and why is this important to the rail sector right now?

What will you be discussing during the Electric & Hybrid Rail Technology Online Conference and why is this important to the rail sector right now?

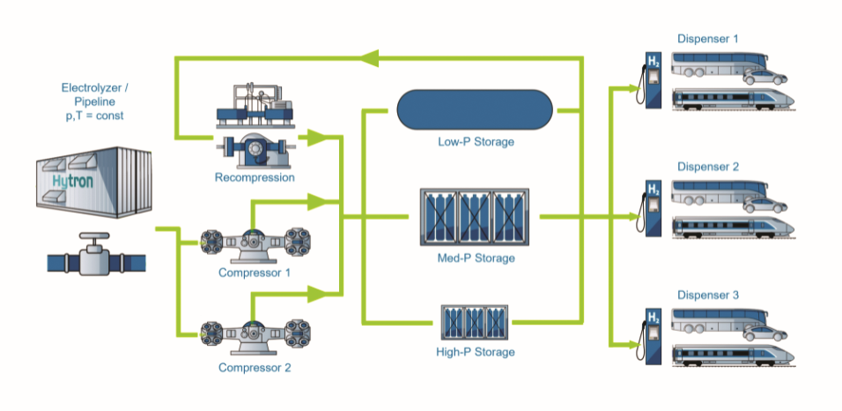

I will be discussing the possibilities of hydrogen in the rail sector - both as a fuel to replace diesel powered trains and locomotives, and the possibilities the rail sector can offer as a means of hydrogen transportation, such as rolling pipelines. Furthermore, I will show how simulation tools can enhance the planning and selection process when building up the required hydrogen refueling infrastructure for rail.

What projects is Neuman & Esser currently working on in this area?

We are currently working on the biggest rail sector hydrogen refuelling station (HRS) intended to refuel a fleet of 27 Alstom iLint trains. Currently we are packaging six compressor units for this HRS.

They are supplied from a pipeline and compress H2 from 6 to 550 bar. Furthermore, we are active on other projects, some with on-site H2 generation via electrolysis, others as a part of a mother-daughter system, and for H2 trailer/container filling.

What are some of the key considerations before embarking on a hydrogen refuelling project for rail?

There are several important factors, but below the key points that need to be considered before the project starts:

- Rough budget

- Available space and plot configuration

- The type of supply, such as on-site generation, pipeline, or trailer supply

- The type of delivery, such as gaseous and at what pressure, and liquid

- The types of trains to be refueled and their tank configuration/size and residual pressure/max pressure

- The fueling pattern – daily or weekly

- Energy supply at the site

Schematics of a pipeline- or electrolyzer-fed hydrogen refueling station

How can simulation help optimize hydrogen refueling stations?

Simulations can help in many ways, such as using them to ensure that the critical tank temperature is not exceeded and to generate a reliable and viable full techno-commercial offer. Using simulation, we can make a good prognosis on fueling times, quality of fill, energy demands, required components and their technical specs, their plot size demand, and their typical costs.

What are some of the unique challenges for hydrogen refueling when compared with diesel?

Compared to hydrogen, diesel as a liquid offers a better volumetric energy density and can easily be pumped into the tank of a locomotive/train. When using gaseous compressed H2 (GCH) it must be compressed and cooled before filling it into the tanks. For liquid H2 it must be cooled down to -253°C and kept cooled at that level to avoid boil-off.

Can existing diesel refueling stations be easily retrofitted so they supply hydrogen?

Mostly, current projects take place adjacent to the existing diesel stations. Conversion from diesel to H2 means a complete replacement, the existing space can be used if the diesel stations are closed.

Is there anything else you would like to add?

The railway system can also play an important bridging role, when the H2 demand is still too small for building a dedicated pipeline but too high for road bound trailer supply. Trains can act as rolling pipelines for hydrogen, supplying several different industries.

To find out more information on Neuman & Esser’s hydrogen compressors, see the company’s exclusive article in the November-January 2022 issue of Electric & Hybrid Rail Technology magazine.